Dipl.ing. Damir Kovač, Dipl. ing.Velimir Ostoić[1]

ABSTRACT: The paper presents implemented physical security systems on an Oil Pipeline Terminal in Croatia, concept of operations and standardized procedures for an effective critical infrastructure protection solution.

KEYWORDS: oil pipeline terminal, critical infrastructure, physical security systems, concept of operations, coastline perimeter protection

Introduction

The Croatian’s crude oil pipeline infrastructure is regarded as a international critical infrastructure, as refineries in Croatia, Bosnia and Herzegovina, Serbia and, somewhat, Hungary, are highly dependent on its storage and transportation capacities. The most critical facility, a crude oil and petroleum products reception, discharge and storage facility lies in a sheltered bay at the Adriatic sea, designed to accommodate up to two VLCC (Very Large Crude Carriers) oil tanker's with a crude oil storage capacity of 1.000.000 m3 and petroleum products of 60.000 m3.

Disruption of the facilities main services may produce not only ecological damages and financial losses, but a long term disruptive cascading effect throughout the region. The responsible Croatian Ministry designated Terminal Omišalj as a part of the national critical infrastructure. According to

administered methodologies, risk assessments were conducted to identify critical facilities, processes and hazards evoked by natural, man-made, technical or technological, biological or chemical processes, upon which guidelines were provided to increase effectiveness of technical protection measures.

In conformity with provided guidelines, the development of project documentation considered comprehensive and optimal solutions that are economically justified and took into account general business, defence, environmental and social interests. The paper shall address the physical protective systems of the facility, describing various implemented systems which exercise the facilities concept of operations.

Facility protection systems

Terminal Omišalj is a part of the crude oil and petroleum products storage and transportation system of the JANAF oil pipeline system. It's located in the northern part of the west coast of the island of Krk, on the peninsula Tenka Punta, between the bay's of Omisalj and Rijeka. It covers a land area of 2700 m in length and a max. width of up to 700 m. The total perimeter of the Terminal is approximately 6.5 km, while its surface area is approx. 1.4 km2.

The Terminal's main services include reception of tanker ships with the help of pilots and tug-boats, unloading and loading of crude oil and petroleum products, crude oil and oil products storage plant, pumping crude oil for transportation through pipelines to receiving refineries and road loading facility for distribution of petroleum products.

Ongoing expansions of services, such as broadening storage capacities for crude oil and petroleum products, capability extensions of the road loading facility and reversible discharge operations are bearing the objective to develop Terminal Omišalj as a favorable Adriatic Center for crude oil and petroleum products storage, supporting efforts for securing European crude oil supply.

Considering above mentioned goals and ongoing operations, a robust layer of security measures are implemented and planned to take effect in parallel to developing investment projects.

The security measures for the protection of critical facilities at the Terminal also consider the support of operational processes of rendered services and safety measures. Protective security measures that are implemented include video surveillance for alarm visualization and surveying activities throughout the Terminal area, access control systems to authorize entrance into facilities or building rooms, intrusion systems to detect unauthorized intrusions to guarded facility zones, coastline surveillance and tracking system to detect vessels and small boats entering the protected coastline area and perimeter protection measures to hinder or prevent possible forced intrusion into the Terminal area.

Further progression of the protection systems, implied their integration with other safety systems such as fire alarm systems. The video surveillance system was extended with thermal cameras, covering the storage area, which may assist fire-fighters during a hazardous event.

Concept of Operation example

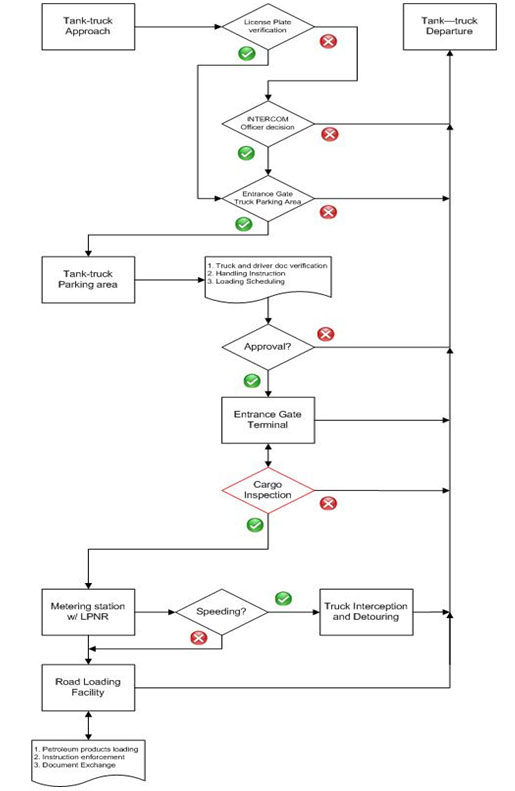

Services provided by the Omišalj Terminal include various operations, such as the loading of petroleum products at the Road Loading Facility. Figure 1 depicts a basic flowchart of such a concept of operation. Basically, implemented protection systems are used to uphold requirements in restricting access to intruders, but also to enforce specified Rules of Conduct. The chosen example defines the road loading process, were a company first announces a tank truck arrival at the Terminal with accompanied documentation for petroleum product loading ( among others, information of the truck’s license plate and driver information).

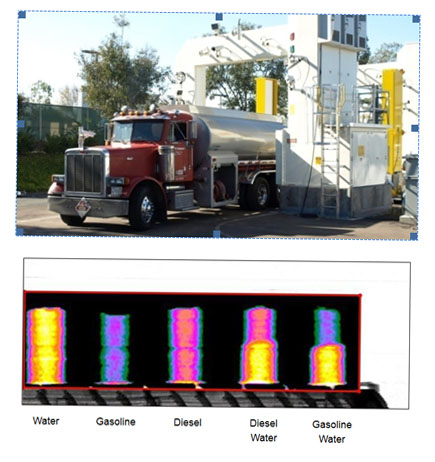

During arrival, a LPNR camera, scans and matches registration plates to a Customer LPRN database, which initiates an automatic opening of a quick folding gate, to grant access to the parking area to approved customers. The driver checks in at the gate entrance with accompanied documents, where, after approval, the truck may enter the Terminal. Entering the Terminal, the truck is scanned by a Cargo Inspection System (not yet installed) for possible malicious packets hidden inside the truck, but also for purposes to ensure what type of liquids are still inside the tanks. At the entrance a wedge barrier system is installed to prevent violent breakthrough into the Terminal by heavy loaded trucks.

Figure 1: Road Loading Facility CONOP

The trucks itinerary to the Road Loading Facilityis video surveyed by the security control officer at the HQ building. On the path strict speeding regulations have to be upheld and are monitored by a speed metering system. At arrival at the RLF, usage instruction must be followed to charge tanks with agreed products, which are video monitored. After the loading operation, the truck is immediately instructed to the Terminal gates, were another Cargo Inspection [1] scan verifies the bulk by discrimination of materials (Figure 2.).Approved shipments pass through the exit gates.

Figure 2: Cargo Inspection – discrimination of petroleum products

Perimeter protections

The well indented, smoothly declining rocky coastline makes the Terminal shores accessible to small vessels and boats. Therefore a surveillance system has been developed to tackle issues of possible sea shore intrusions.

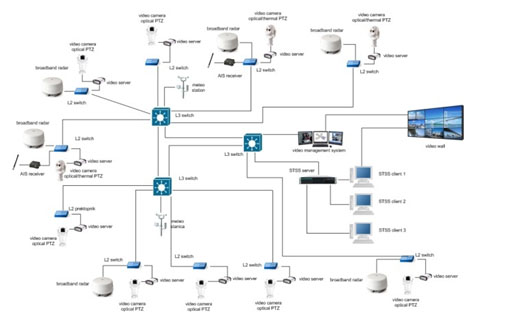

Figure 3: Coastline Surveillance and Tracking Security System – STSS-Carchitecture [2]

The STSS-C (Figure 3.) is a 3-tiered perimeter system based on strategically deployed low emission X-band radars,which track objects approaching shores.

The system integrates automatically on target aimed optical and thermal cameras for visual alarm confirmation, automatic vessel identification system for SOLAS vessels and meteo stations to automatically optimize system components to current meteorological conditions. The second implementation phase widened the systems feature with a fence radar system which guards the mainland perimeter in a zoned 3m width and 8m high virtual intrusion protection space. Possible intrusion alarms are, again, visually confirmable via target centered PTZ cameras.

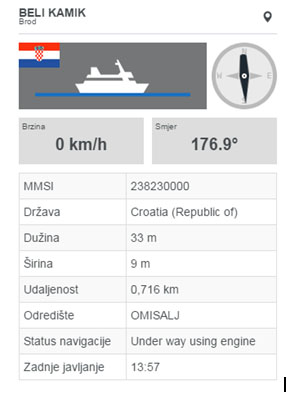

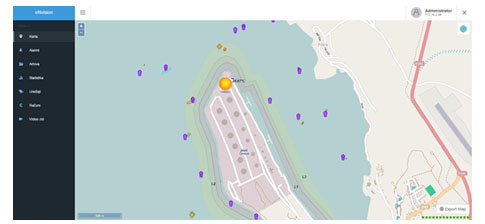

Further expansions may include integration of long range acoustic devices for direct audible communication with targeted objects/persons that are violating the tiered perimeter along the shore and mainland borders. The interactive map feature [Figure 5.] displays active, detected geo-referenced targets and installed devices that are integrated into the solution. Each target may be selected separately to display target information as target (ID, AIS, meteo, target speed, target bearing, and other specific details) and device data and current status. Radar measurements are usually insufficiently accurate in determining size, bearing and speed of detected objects, mainly induced by environmental noise and unpredicted movements of objects. An object tracking algorithm calculates object centroidsin radar scanning cycles to determine object bearing and speed, through hypothetical/statistical mathematical methods and object trajectory alterationprobabilities.

Figure 4: Vessel AIS information

Figure 5: Interactive map with tracked objects

The tiered perimeter is based upon security levels based on the maritime International Code for the Security of Ships and Port Facilities. The tiers may be configured with wider zones around the coastlineupon proclaimed severity levels, which then result with earlier detection and alarming of potential threats.

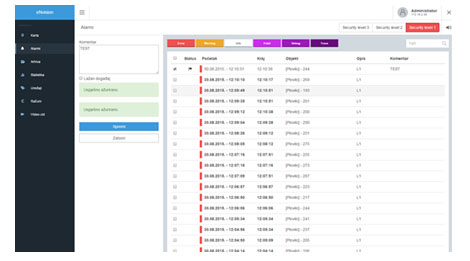

Figure 6: Alarm management

All detected objects entering different security tiers are classified upon their intrusionlevels and are therefore treated with different priority levels. An alarm management platform [Figure 6.] is offered to accept, dismiss and comment specific alarms.

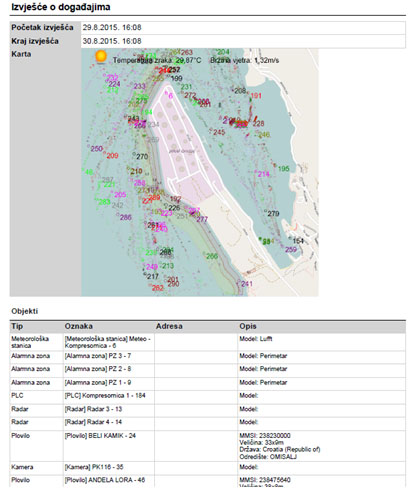

Incident reports may be created through a specific timeframe, in which the system is acquiring all available data. Incident reports are created in a portable document format which may be saved or printed separately [Figure 7]. Export of historical data into video format is also available for creation in a specified timeframe, which depicts all acquired objects and their trajectories displayed previously in the interactive map.

Figure 7: Report sample

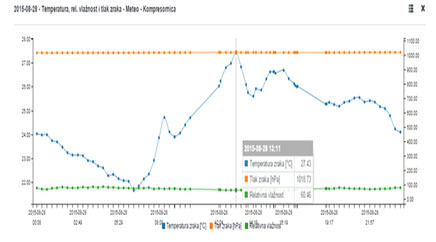

Meteorological real-time information are used to reconfigure radar functions for optimized operations in all weather conditions (environmental noise suppression in radar scans), but are also used in the decision making process for accepting tanker ships entering Omišalj Bay for tug-boat and pier docking operations.

The meteo data (min/max/avg values for cold/warm days, wind class, relative humidity, and precipitation per day/month/year) are comprised for trend reporting, which enables decision making for planning and preparation of different technological activities, including comparison to intrusion alarm reporting.

Figure 8: Graphical statistics of meteo data

Conclusion

The paper presents a developing protection system of an oil pipeline facility, describing different protection systemapplication supporting security, control, decision making and various technological processes.

Integration of video surveillance, access control, intrusion alarm systems, cargo inspection, perimeter protection (coast- and land-line), fire alarm, oil spill prevention systems and other, into a comprehensive security and safety solution, provide possibilities to ensure fast operator response to occurring threats or hazards. Analyzing historic events and alarms, prediction of repetitive behavior may be identified and countermeasures may be planned to hinder or prevent such actions.

Continuous efforts undertaken by the oil pipeline operator, JANAF Plc, insure implementation of cutting edge technologies and innovative solutions for integrative protection systems, offering customers secure and stable services.

References

1. Leidos, Inc., VACIS® IP6500 Cargo Inspection System

2. Teltronic d.o.o.: Surveillance and Tracking Security System

[1] Adriatic Security Solutions d.o.o., Radnička cesta 39, 10000 Zagreb, Croatia, damir.kovac@ass.hr, velimir.ostoic@ass.hr